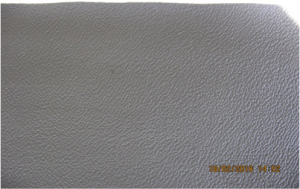

patex serie hs

Eco-Pelle sistema alto solido a base PUPerché usare PU HS SARP OX FREE

FTALATE FREE

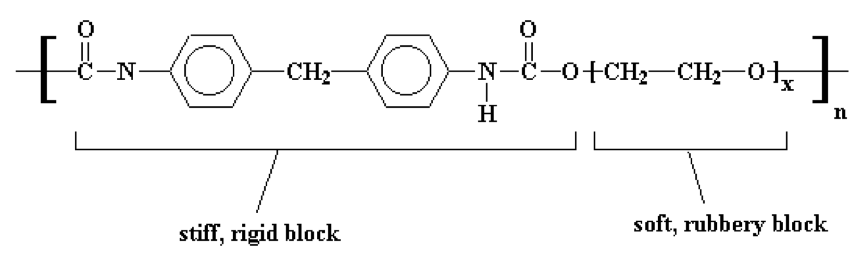

Il sistema HS SARP OX FREE è un insieme di polimeri a base poliuretanica. Questa composizione è particolarmente elastica e non necessita di plastificanti per rendere il materiale flessibile e plastico. Non sono quindi necessari gli FTALATI che rientrano nella Prop 65 della California come sostanze indesiderate e nemmeno gli FTALATI che fanno parte della Candidate List del Reach europeo. Possiamo dire che gli HS SARP OX FREE sono FTALATE FREE

DMF FREE

Il sistema HS SARP OX FREE è un insieme di poliuretani ad alto solido che non contiene il solvente DMF e non necessita di essere diluito con questo solvente per essere spalmato e lavorato. Questo permette di eliminare un solvente tossico che rientra sia nella Prop 65 che nella Candidate List del Reach. La DMF è indispensabile nella produzione dei coagulati PU perché è solubile in acqua e permette ai poliuretani di coagulare sui vari supporti. Il sistema HS SARP OX FREE è una valida alternativa ai coagulati poliuretanici e il processo è DMF FREE.

SOLVENT FREE – VOC FREE

Il sistema HS SARP OX FREE non contiene solventi, quali alcol, toluene o glicoli come altri poliuretani perché è basato su una polimerizzazione in massa dispersa e quindi non necessita di un mezzo solvente per avvicinare le molecole e farle reagire. Non fa parte quindi di quei poliuretani che pur essendo DMF free, contengono altri solventi con emissioni differenti dalla DMF ma che comunque rimangono e non vengono eliminate. Per questo motivo possiamo dire che gli HS SARP OX FREE sono SOLVENT FREE e di conseguenza VOC FREE

OXIME FREE

Una particolarità importante dei poliuretani HS SARP OX FREE è l’assenza di ossime, che vengono utilizzate durante la polimerizzazione di poliuretani ad alto solido e che conferiscono al prodotto un odore particolarmente fastidioso. Grazie agli studi effettuati presso il nostro laboratorio e in collaborazione con docenti del Politecnico di Milano siamo riusciti ad ottenere il brevetto n° 10201500016593 che attesta un processo innovativo e prodotti con una qualità non esistente in precedenza e questo senza l’uso di chetossime. Possiamo quindi dire che gli HS SARP sono OSSIMA FREE.

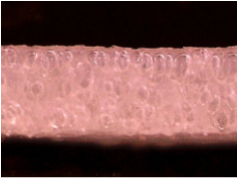

ESPANDIBILI

I prodotti HS SARP OX FREE sono poliuretani senza solventi e quindi possono essere addizionati con agenti espandenti in grado di sviluppare una struttura cellulare aumentando lo spessore a parità di peso. Questo permette di abbassare il peso dei prodotti finiti a parità di spessore, così come si fa normalmente con i prodotti in PVC. Inoltre la densità del polimero non espanso è inferiore del 35% rispetto al polimero PVC. Possiamo quindi dire che gli spalmati HS SARP OX FREE sono una valida alternativa agli spalmati in PVC.

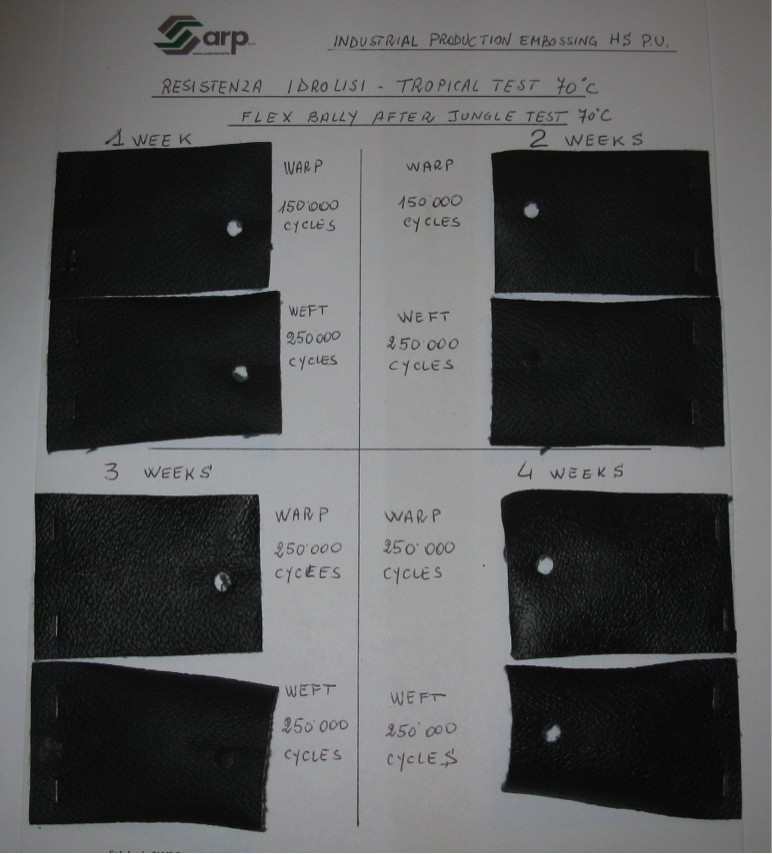

RESISTENTI all’IDROLISI

I prodotti HS SARP OX FREE sono poliuretani a base polietere, differenti dalla maggior parte dei poliuretani che sono a base poliestere. Questa differenza è molto importante per la “vita” del polimero che come abbiamo detto è soggetto alla degradazione per effetto dell’acqua e della temperatura. La presenza di una lunga catena a base etere e quindi idrofoba rende questi polimeri meno attaccabili e più resistenti nelle normali condizioni applicative e particolarmente adatti nei settori dell’arredamento e dell’automotive.

RESISTENTE AI SOLVENTI

I prodotti HS SARP OX FREE formulati, catalizzati e reticolati come indicato nelle schede tecniche costituiscono un film elastico e flessibile, insolubile non solo nei tradizionali solventi tecnici ( in grado di garantire incollaggi molto forti, toluene, glicoli) ma anche nella DMF. Questa caratteristica permette l’uso di colle aggressive in grado di garantire incollaggi molto forti, anche in posizioni difficili.

BIODEGRADABILI

I poliuretani in generale e quindi anche quelli del sistema HS SARP OX FREE sono polimeri che contengono legami chimici uretanici, molto polari perché costituiti da carbonio, ossigeno e azoto. Questa polarità permette all’acqua, al vapore acqueo e all’umidità, con l’aiuto della temperatura, di attaccare il legame, di provocarne la rottura e di demolire il prodotto. Sono perciò materiali compostabili e degradabili, compatibili con l’ambiente.

BIOCOMPATIBILI

I prodotti HS SARP OX FREE, formulati e lavorati come indicato dalla nostre specifiche tecniche, superano la norma ISO 10993 parte 5 e parte 10 per la biocompatibilità: i risultati sono decisamente positivi, quindi si può dichiarare che questi materiali sono biocompatibili, cioè non sono citotossici, non provocano allergie e irritazioni cutanee. Possono dunque essere utilizzati senza problemi anche per materiali a contatto con la pelle. La conferma deriva dal fatto che non contengono i prodotti elencati dallo standard ecologico europeo OEKOTEX standard 100 per l’uso dei materiali a contatto con la pelle (classe II)

RESISTENTE NEL TEMPO

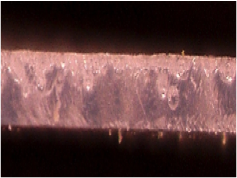

Risultati resistenza all’IDROLISI

Tropical Test – temperatura 70°C – Umidità 95% – tempo 1 – 4 settimane

SCHEMA di PROCESSO per Patex HS

- PATEX SR 20

- Colori PATEX SERIE HS

GOFFRABILE CON CILINDRO CALDO

GOFFRABILE CON INFRAROSSI

ESPANDIBILE

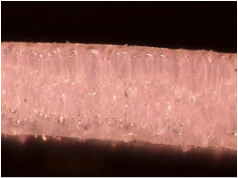

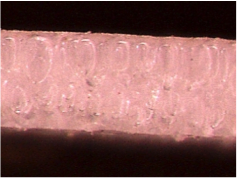

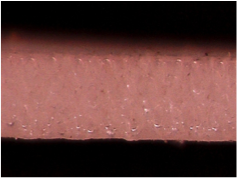

Risultati di espansione

PATEX HS – peso di spalmatura 300g/m²

quantità di PATEX BLOWING 50

0% – 3% – 6% – 9% – 12%

0%

3%

6%

9%

12%